0755-8253 2401

0755-8253 2401 Industrial Applications of Reed Switches

Reed switch sensors work with programmable logic controllers (PLCs) and microcontrollers over a wide operating voltage range and offer high speed operation. When used with a weak magnet, reed sensors can also detect any ferrous metal part.

Reed Switch Safety-Oriented Applications

Fiber optic sensor lenses require exceptionally clean guidance for sensing applications. A reed switch and magnet are combined into an assembly with a specific distance between them, creating a normally closed (NC) reed switch sensor. When a permanent magnet section comes between them, the magnetic field begins to shunt, and the reed switch opens. A normally open (NO) reed switch sensor can be designed using a normally closed reed switch on one side and a magnet on the other, sufficient to keep the normally closed reed switch open. Reed switch-based sensors can operate in very dirty industrial environments, where grease and dust do not affect their operation. Common applications include conveyor belt section sensing and industrial agitator speed sensing.

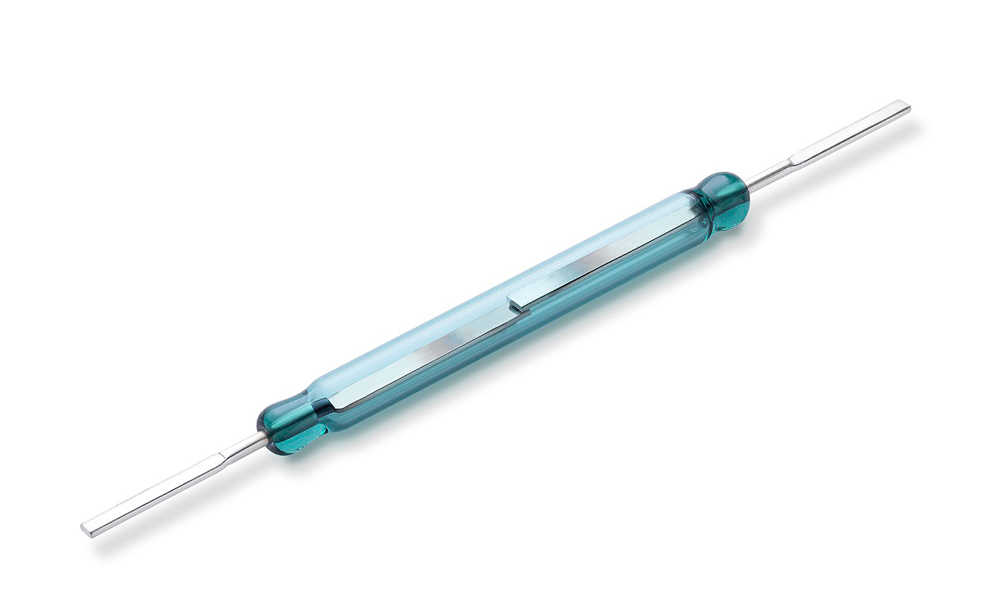

End position sensing in cylinder and piston

Most cylinders, pistons, linear slides, and rotary actuators have built-in magnets for end position sensing. Reed switch sensors are used to sense end and intermediate positions, and the signals can be processed for further indication in PLC applications. Reed switch sensors offer very high detection speeds, allowing them to work well with high-speed PLC programs. Reed sensors can also be equipped with indicators (LEDs) to help easily adjust piston and cylinder stroke or rotary actuator angles.